Green Hydrogen in Industry

Green hydrogen is a clean, renewable energy source that is revolutionizing the industry. By using renewable energy to produce hydrogen from water, this technology offers an alternative to fossil fuels, reducing carbon emissions and helping to combat climate change. In this article, we’ll explore the different ways in which green hydrogen is produced, stored and used in industry, as well as its economic and environmental benefits. We will also discuss the current challenges and future opportunities for this emerging technology.

I. Context on the Urgency to Reduce Carbon Emissions in Industry

In many sectors, urgent action is needed to reduce carbon emissions, particularly in manufacturing industries.

The manufacturing industry is one of the largest greenhouse gas emitters globally, responsible for about a third of total CO2 emissions. Energy production, transport, agriculture, manufacturing industry, chemical processes and construction materials are the main contributors to these emissions.

Climate change poses a growing threat to the planet, manifested in extreme weather events, glacier melting, rising sea levels, and ecosystem disruption. To limit the impacts of climate change, reducing greenhouse gas emissions is crucial, and the industry must play an active role in this transition.

Governments worldwide have begun taking steps to limit carbon emissions from industry by imposing stricter regulations on greenhouse gas emissions and encouraging the adoption of cleaner and more efficient technologies. However, these efforts alone will not be sufficient to achieve global emission reduction goals.

Therefore, many companies are seeking alternative solutions to reduce their carbon emissions, including adopting renewable energy production technologies, improving energy efficiency in their processes, and investing in innovative technologies like green hydrogen.

Green hydrogen in the manufacturing industry is a promising solution for reducing the sector’s carbon emissions. By producing hydrogen from renewable energy sources such as solar, wind or hydro, green hydrogen can offer a clean, sustainable alternative to fossil fuels for power generation and industrial processes.

II. What is Green Hydrogen?

What exactly is green hydrogen? Production, manufacturing …

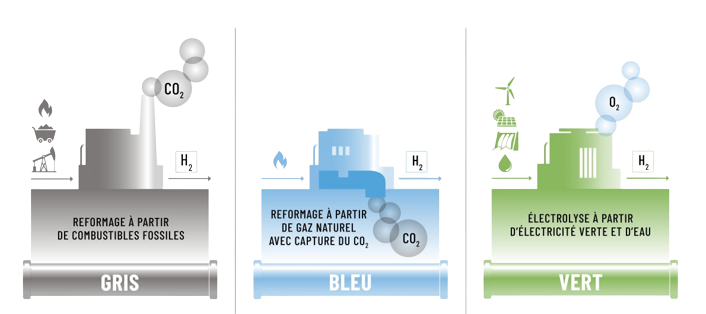

Green hydrogen is produced from renewable energy sources such as solar, wind, or hydroelectric power, which do not produce greenhouse gases. Unlike gray or blue hydrogen, which are produced from fossil energy sources like natural gas, green hydrogen has an extremely low environmental impact.

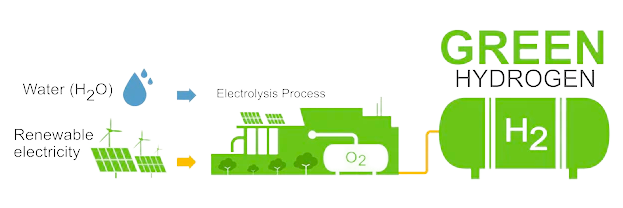

There are two methods to produce green hydrogen: electrolysis of water and biomass gasification.

Method 1: Water electrolysis

Water electrolysis is the process of separating the basic components of water, hydrogen and oxygen, using an electric current to “break down” the water molecules. The source of electricity for this action comes from solar or wind power.

Method 2: Biomass gasification

Biomass gasification is the process of converting organic matter (compost, animal dung, organic waste, etc.) into synthetic gas (or syngas): the basis for the subsequent production of hydrogen. In this process, organic matter is heated to high temperatures in the presence of a gasifying agent, such as steam or oxygen. The organic material then decomposes into a gas, which is then treated to separate the hydrogen.

For the time being, one drawback is the rather high cost of green hydrogen production compared with other, less sustainable types of hydrogen.

However, this alternative remains an interesting avenue for the environmental transition of manufacturing industries.

III. Presentation of Green Hydrogen as a Promising Solution

Hydrogen, the most abundant element in the universe, can be produced from many green and less green energy sources.

Its applications are diverse:

- powering industrial processes,

- operating vehicles and equipment emission-free,

- storing or transporting energy for on-demand use at various sites,

- power fuel cells for electric vehicles, buildings, data centers and other equipment, offering a clean, efficient alternative to traditional combustion systems.

IV. Advantages of Green Hydrogen in Industry

The main advantages of using green hydrogen in industry include:

- Reducing greenhouse gas emissions: One of the main advantages of green hydrogen is that it significantly reduces greenhouse gas emissions in industry. As mentioned above, it is produced from renewable energy sources: its production therefore generates very low greenhouse gas emissions (we can’t say that they are zero, since the manufacture of renewable energy infrastructures itself emits greenhouse gases). It can be a relevant lever in the drive to reduce CO2 emissions and move towards carbon neutrality.

- Versatility: Green hydrogen can be used in various industrial applications, including heat and electricity production, fertilizer production, and chemical manufacturing.

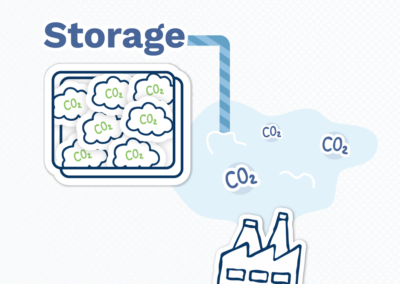

- Energy storage: Its ability to be stored makes it a valuable asset for temporary energy storage, anticipating and reacting when other energy sources are not available.

- Performance: When used to power fuel cells, hydrogen’s efficiency exceeds that of internal combustion engines, helping industries improve energy efficiency and reduce their fossil fuel consumption.

- Noise and odor reduction: Using green hydrogen can also help reduce the noise and odors associated with industrial processes, unlike fossil fuels.

V. Applications of Green Hydrogen in Industry

In this section, we explore the various applications of green hydrogen in the manufacturing industry.

- Power generation: Green hydrogen can be used to generate electricity in power plants. Fuel cells can convert hydrogen into electricity, generating clean energy.

- Heating and cooling: these are two processes frequently used in industry. Hydrogen boilers can replace natural gas boilers for heating buildings. Absorption refrigerators can also be powered by hydrogen, which reduces greenhouse gas emissions.

- Transport: Hydrogen-powered vehicles can offer a clean, efficient alternative to fossil-fuel vehicles, trains and ships, especially for the transport of goods and raw materials.

- Chemical industry: Production of basic chemicals such as ammonia and methanol, to name but a few.

VI. Future Perspectives of Green Hydrogen in Industry

In the final part of the article, we explore the future prospects of green hydrogen in the manufacturing industry.

Increasing Production: As the demand for green hydrogen rises, its production costs continue to decline. Concurrently, more companies and governments are adopting carbon neutrality goals, encouraging initiatives towards diversifying energy sources.

Growing Demand: Industries require sustainable solutions to meet their greenhouse gas emissions reduction goals, and green hydrogen offers a promising solution. Therefore, the demand is expected to continue growing in the coming years.

Development of New Markets: Industries increasingly recognize the opportunities of green hydrogen in terms of environmental impact and financial gains.

In Conclusion: Green hydrogen offers numerous promising prospects for the industry. Its manufacturing process is constantly evolving, and this solution is expected to become increasingly competitive compared to fossil fuels. Its advantages in reducing greenhouse gas emissions, versatility, energy storage, performance, and noise and odor reduction make it a key energy source for achieving carbon neutrality goals.