Industrials: What Solutions Lead to Water Conservation?

In 2022, France was once again hit by drought. This phenomenon is expected to recur and intensify. As a result, companies must adapt to limit their water consumption and avoid shutdowns. From optimizing cleaning-in-place processes to using predictive software, here’s an overview of solutions offered by Dametis with Alexandre Sailer, Sales Manager at Dametis.

“Companies facing the reality of a semi-arid France,” headlined Les Echos in August 2022. Seven months later, in March 2023, President Emmanuel Macron presented his “water plan,” setting a goal of “10% water savings” by 2030. Companies are at the heart of this change. In 2018, industrials and the agricultural sector consumed 5.4 billion cubic meters of fresh water per year. According to Alexandre Sailer, “faced with the risk of shortages, companies must reduce their water consumption.” A significant challenge, but solutions do exist. Let’s see how to strive for water conservation.

What is Water Conservation?

The term water conservation is increasingly used, but what does it really mean? Conservation refers to moderation, and the adjective water-related refers to water. Therefore, water conservation simply means limiting water consumption. Throughout this article, we will explore how industrials can implement this principle of water conservation.

I. Map Your Plant to Measure and Control

“You only control what you measure,” emphasizes Alexandre. Thus, his first recommendation for reducing water consumption is to understand it. One must “have a map of water uses within the company to understand its operation. This allows targeting discharges and needs.”

The collaborative and predictive software MyDametis allows for 24/7 data availability of your company on a single interface, facilitating this mapping. This tool accelerates decision-making, enables concrete improvements on performance indicators, and thus enhances water consumption control.

” With the data collected, we found several losses for one of our clients; valves were not closed, non-functional machines continued to consume water… This observation led to solutions. The amount of water used was halved. “

II. Undertake Work to Correct

This tool also helps correct practices or habits, potentially leading to work implementation. For example, adjusting machine settings, sealing leaks, eliminating cooling of lost water. Optimization work can also be undertaken, such as looping certain uses. For instance, water used to cool pump seals can be used in the composition of a paper pulp recipe.

Several companies already use MyDametis in this way, such as Agromousquetaires Lactalis and another international agri-food group.

III. Optimize Cleaning-in-Place to Reduce Consumption and Water Pollution

To further reduce water use, cleaning-in-place (CIP) must be optimized. This process is most commonly used in the agri-food and cosmetics sectors. It allows cleaning equipment without disassembly. However, this method is costly in terms of time and water. As Alexandre Sailer recalls, “overconsumption of water has several consequences.” “Indeed, there is the economic cost of water, but it’s more complex. It requires more energy, more personnel, occupies line opening time, and overly strains the water treatment system. “

Dametis optimizes this cleaning using three fundamental principles: Reduce, Reuse, and Recycle. To achieve this, we have three tools: BarCIP, to analyze CIP operation; OptiClean, to measure its efficiency and reduce cleaning time; and Green CIP, to infinitely reuse cleaning solutions. These tools are developed in partnership with Elodys and its founder Olivier Barrault, who reminds us, “focusing on decarbonization without considering water is only seeing the tip of the iceberg.”

IV. A High-Performance Treatment Plant for Water Conservation

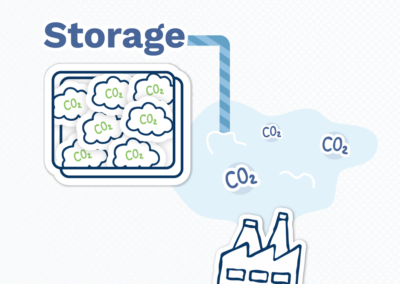

MyDametis and the tools implemented to perfect CIP reduce the amount of wastewater, thus the amount of water to be discharged into the environment. “This equipment consumes between 3% and 6% of a site’s total energy,” recalls Mathias Welschbillig, an environmental expert. This is a first step towards water conservation.

In the context of environmental transition, Dametis offers to analyze and improve the efficiency of the treatment plant, reducing its cost and water consumption, and to install a methanation module. An investment with multiple benefits as it produces biogas, a green energy, reduces the amount of effluents, and allows selling the sludge from methanation as fertilizer for farmers.

V. Optimization and Recycling, Currently Hindered by Existing Regulations

“Once consumption is reduced, one must think about reusing it,” summarizes Alexandre Sailer. Currently, “less than 1% of its wastewater reused […], France is one of the poor performers: the European average is around 7% ” recalls a Challenges article titled “ Water: the industry will also have to switch to water conservation, ” published in January 2023.[5]

However, these measures also require “State support,” recommends Alexandre Sailer. “Currently, to be able to reuse all the water in a plant, extreme process security is needed. It’s not impossible, but it’s very difficult to implement. The government must facilitate this and support industrials with aids. The administration must also create a legal framework and regulatory controls to govern industrial responsibility in this practice. This is the only way we can progress quickly. “

[2] https://www.lemonde.fr/planete/article/2023/03/31/le-plan-eau-d-emmanuel-macron-est-avant-tout-un-appel-a-la-sobriete-de-tous_6167682_3244.html

[3] https://www.dametis.com/mydametis/

[4] https://www.dametis.com/limiter-votre-consommation-deau/

[5] https://www.challenges.fr/green-economie/eau-l-industrie-va-aussi-devoir-se-convertir-a-la-sobriete-hydrique_843288